Introduction

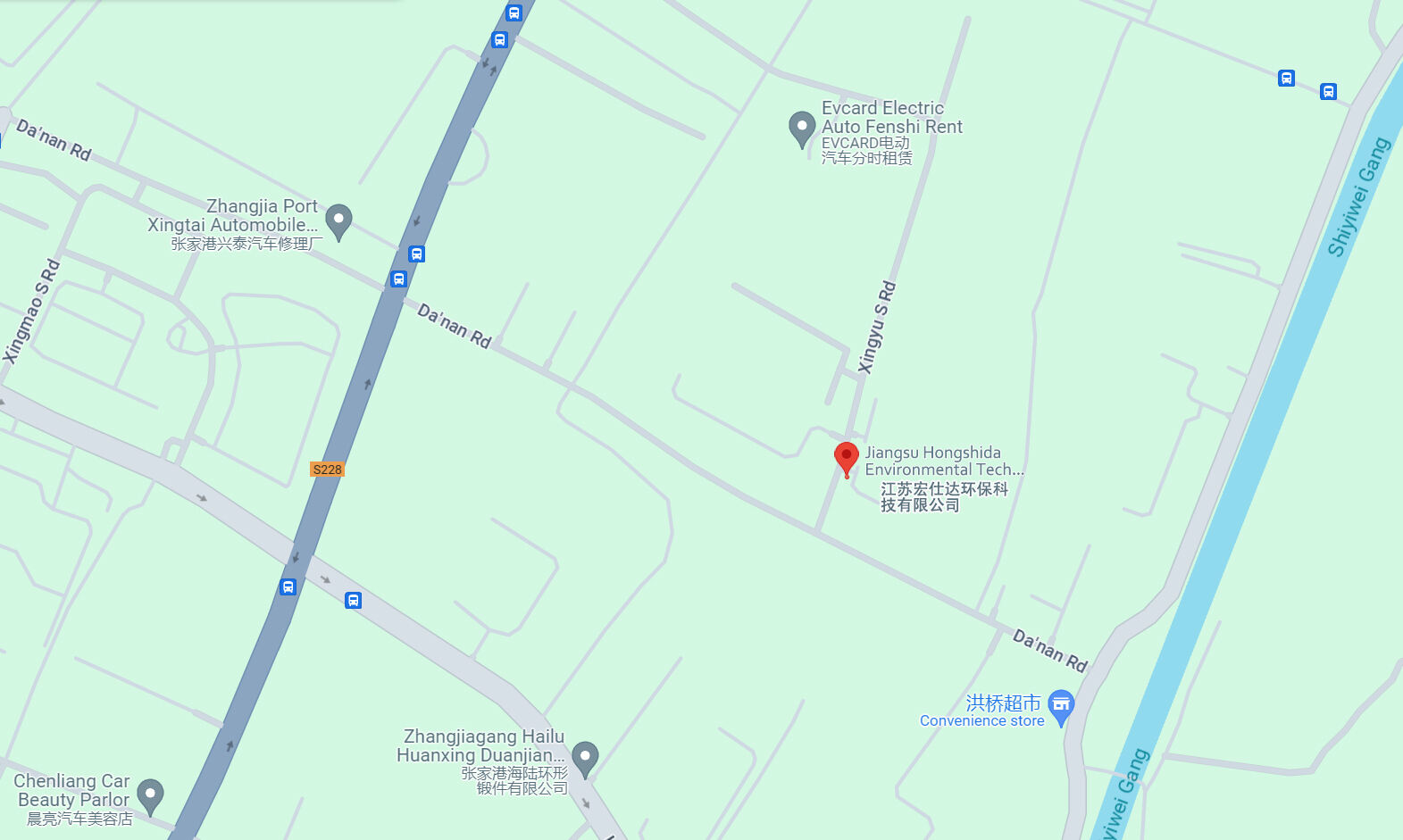

The Chinese market for air filter end caps provides numerous suppliers together with affordable pricing therefore many industries in the market choose Chinese imports. Manufacturers in China provide air filter end caps at various quality levels so you need to research extensively and use specific methods to check if purchased items match your requirements. The following article presents essential steps for obtaining quality air filter end caps from China suppliers like Jiangsu Hongshida.

Research Potential Suppliers

Verify Legitimacy

Businesses must first confirm the validity combined with the reliability of potential suppliers by investigation before starting any cooperative work. The online platforms Alibaba and Global Sources and Made-in-China help you access buyer feedback about suppliers through review sections. You should verify the supplier has both verified member status and relevant certifications. The initial step of supplier verification separates genuine suppliers from untrustworthy ones by revealing which suppliers have successfully delivered expected results in past transactions.

Evaluate Experience

The production experience significantly impacts the quality of manufacturing precision items that include air filter end caps. Suppliers operating within the industry for an extensive period tend to maintain stable and reliable quality control measures. Assess supplier experience through their business duration and clientele and memberships from relevant industry bodies. Reliable manufacturing depends on established suppliers because they offer better reliability while maintaining product quality even when handling large orders.

Request Samples

Inspect Quality

A supplier evaluation depends heavily on taking delivery of examples since it remains a fundamental inspection method. Tests enable you to determine the quality attributes of materials before production as well as the manufacturing process and finished items. Carefully inspect all received materials to search for any issues that would affect their operational quality. A physical review of the products through samples will better help you understand what the bulk shipment will look like.

Compare Multiple Suppliers

Evaluating your supplier requires investigation beyond one company. Send test samples to different suppliers for checking how their products compare in terms of quality along with pricing and customer care services. A broad sampling process enables you to identify the supplier that meets your quality requirements while delivering maximum value. Evaluation of multiple suppliers will strengthen your position during price negotiations with the selected supplier.

Conduct Factory Audits

On-site Visits

Organize on-site inspections at the facilities of prospective suppliers whenever it is possible. Gaining access to manufacturing operations allows you to see their actual production potential and quality management systems and workplace environment. The inspection of supplier facilities can be outsourced through Chinese-based third-party companies when personal site visits are impossible.

Production Standards

The audit needs to focus on reviewing both production standards and quality control measures that suppliers implement. The supplier needs to maintain compliance with international manufacturing requirements while implementing stringent quality assurance method. The factory's possession of ISO standards can act as proof of their dedication to quality standards in production.

Negotiate Clear Agreements

Detailed Specifications

When selecting vendors you should make sure all product requirements alongside quality standards and delivery deadlines get included in your precise contractual agreements. A clear definition of your preferences prevents misunderstandings to guarantee accurate understanding from suppliers about their deliverables. Every design specification must be recorded including the utilized materials and sizes alongside performance benchmarks and packaging protocols.

Quality Assurance Clauses

The contract needs to include quality assurance clauses as part of the agreement. Description of inspection methods combined with acceptance conditions together with protocols for failing to meet standards should appear in the contract's clauses. Strong contractual agreements protect companies from receiving poor products while allowing them to take legal course in case their delivery terms go unfulfilled.

Perform Regular Inspections

Pre-shipment Inspections

Before leaving any shipment factory, it is important to conduct pre-check inspections. This ensures that the products meet your quality standards and reduce the risk of obtaining defective or non-non-compliance items. You can rent third-party quality inspection services to complete these inspections and provide comprehensive reports on products.

Continuous Monitoring

Maintaining quality should be a continuous process. Continue monitoring the quality of the products obtained during each shipment and provide constant response to the suppliers. Establishing a regular inspection process strengthens your relationship with the supplier and ensures that they are committed to maintaining high quality.

Conclusion

Ensuring the quality of air filter and caps when purchasing from China includes a multidimensional approach. By doing research on potential suppliers, requesting and comparing samples, conducting factory audit, interacting on detailed agreements, and regular inspection, you will be better equipped to secure products that meet your standards. After these stages, not only helps to purchase high quality end cap, but also makes a permanent relationship with reliable suppliers, thus enhances the overall success of your business operations.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MK

MK

KA

KA

UR

UR

BN

BN