Deriving industrial air filter performance quality and durability and cost management from appropriate expanded metal mesh choice remains essential. The filtration system depends heavily on expanded metal mesh since it supports filter media while maintaining efficient air passage. The following text provides essential information necessary for selecting expanded metal mesh when building industrial air filters.

Understanding Expanded Metal Mesh

A metal sheet becomes an expanded metal mesh through a process of deep cutting followed by stretching which develops interconnecting strands that create openings throughout the surface. The design of interconnected strands in combination with high open area percentage gives the mesh its strong characteristics that make it suitable for air filtration uses. The manufacturing material consists of stainless steel aluminum and carbon steel which provides separate strengths and anti-corrosion abilities and weighs varying amounts.

Material Selection

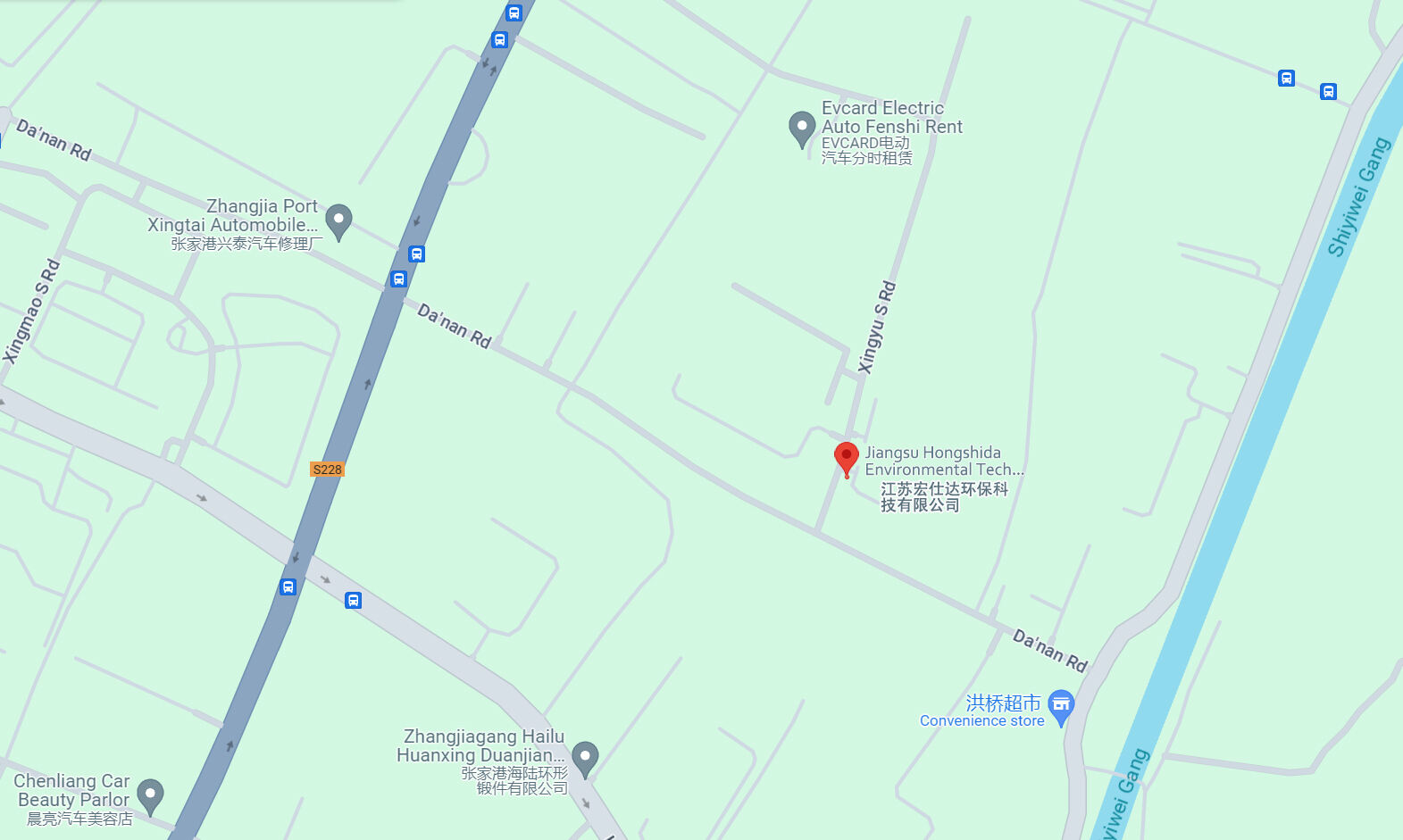

Material selection by Jiangsu Hongshida stands as the primary factor to evaluate before making any decision. Multiple industrial needs call for different material choices because environmental elements and durability requirements alongside expense levels determine the best solution. For example:

Stainless Steel: Stainless steel serves applications needing both corrosion resistance together with significant strength because it displays high resistance to corrosion and shows excellent strength properties.

Aluminum: Aluminum provides both weight-saving properties and excellent resistance to oxidation and serves well in portable equipment needs.

Carbon Steel: The strength and affordability of carbon steel material makes it suitable for applications requiring less protection against corrosion damages.

Mesh Size and Thickness

The efficiency and total strength of the filter depend heavily on its mesh dimensions and its thickness. The filter's airflow relationship and its power to trap contaminants depend directly on mesh size which represents the size of its openings. Meshes with tight openings will efficiently collect smaller contaminants despite causing reduced airflow that increases pressure losses and power usage.

The selection of mesh size should align both filtration effectiveness and air capacity. Mesh openings should be small to achieve effective filtration but need to be big enough to let adequate airflow for coarse filtration.

The filter mesh durability together with structural rigidity depends on its gauge measurement. Mesh thickness plays an important role because a thicker design increases durability when subject to high pressure and wear yet it affects system weight while raising equipment costs.

Open Area Percentage

The open area percentage represents the relation between open spaces and mesh surface area. The filter's airflow pattern together with air resistance depends directly on the open area percentage. The amount of open space determines the filtration efficiency and pressure drop characteristics and works best in fluid systems where rapid air velocity is present. A higher open area percentage will negatively affect the mesh framework's structural stability when used without a sufficient support system. Creating an appropriate balance between open area and filter strength and durability forms a vital concept when designing a filter.

Surface Treatment and Coatings

Surface treatment as well as coating technologies increase the functional life and operational performance of expanded metal mesh. Three standard treatments used for expanded metal mesh are galvanization anodizing and powder coating.

Galvanization: Galvanization converts the mesh through zinc coating to achieve superior resistance against corrosion which works excellently in both outdoor areas and humidity-prone conditions.

Anodizing: Aluminum meshes benefit from anodizing treatment because it strengthens both resistance to corrosion and surface material hardness.

Powder Coating: Powder Coating requires heating treated mesh to cure a dry powder coating which delivers long-term durability and weather resistance.

The selection of a suitable surface treatment together with appropriate coating depends entirely on operational needs and environmental conditions.

Customization Options

Industrial air filters need individualized solutions to fulfill particular implementation requirements. Human-made expanded metal mesh holds three customization areas:

Shape and Design: They can manufacture mesh into diverse filter housing shapes and designs.

Perforations and Patterns: Particular filtration needs can be optimized through custom perforations added to the mesh structure.

Framing and Edge Treatments: Professional framing applications and edge finishing packages work to improve installation simplicity as well as reinforcing the structural components.

The customization of your application requires joint work between you and manufacturers to create a solution that fulfills every requirement.

Multiple factors determine the suitable selection of industrial air filter expanded metal meshes including materials and dimensional parameters, open area ratio and additional treatment requirements and manufacturing specifications. Keeping these factors in mind, you can ensure that your filtration system is efficient, durable and cost effective. This broad approach will help you achieve optimal performance and longevity in your industrial air filtration applications.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MK

MK

KA

KA

UR

UR

BN

BN